Projektteam

J. Sasse, R. Jenke, RWU Ravensburg-Weingarten University ofApplied Science

L. Prasolb, Hilti AG

1.Problem statement

- High costsformillingtoolsin machining (Fig. 1) and missingroot cause:

- Notransparencyaboutreal toolwear

- Different operatinglifetimesdue toheuristics-basedsetupandexchangeofmillingtoolsbyworkers

-

Task: Perform association analysis to determine relationships and influencing factors on tools‘ lifetime* and determin suitable measures to optimize tool usage in machining

(*measured by parts produced during lifetime)

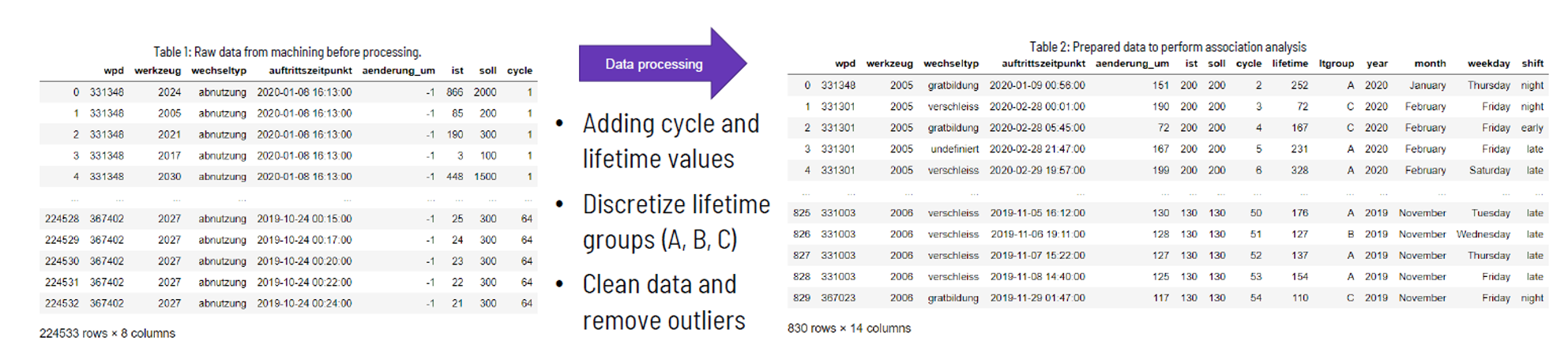

2.Data processing

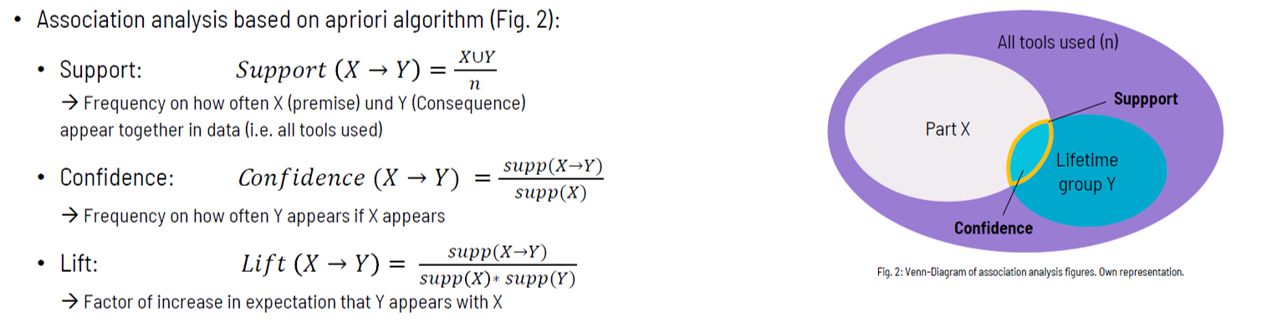

3.Method

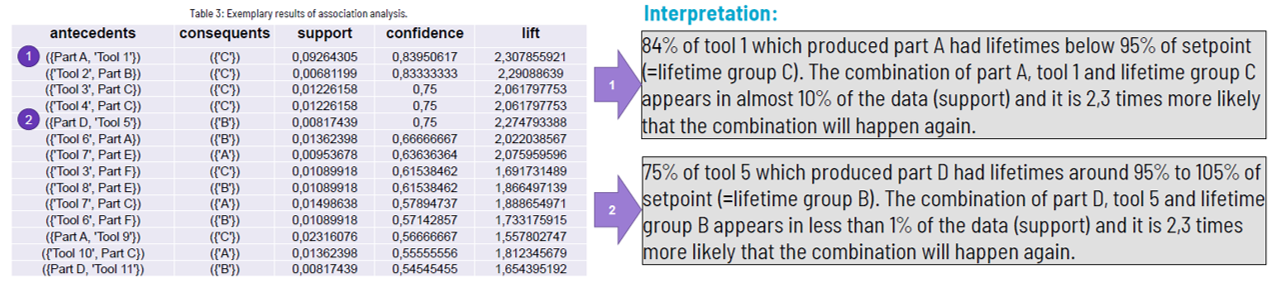

4.Results

5.Future Perspective

- Individual tool settings for each tool-part-combination to optimize tool usage

- Use of model as data-based decision support regarding tool exchanges and tool life adjustments which could also be replenished by cost/time optimized tool changes (Fig. 3)

Literature

- Sasse, J. (2020): Process Mining in der Produktion –Durchführung einer Datenanalyse in der spanenden Fertigung. Master Thesis, RWU.

- Cleve, J. & Lämmel, U. (2016): Data Mining. De Gruyter Studium, 2nded., Berlin: De Gruyter.

- Kröckel, J. (2019). Data Analytics in Produktion und Logistik. 1. Auflage, Vogel